What are the Differences Between Plastic Injection Part & Machined Plastic Part?

2025-07-18

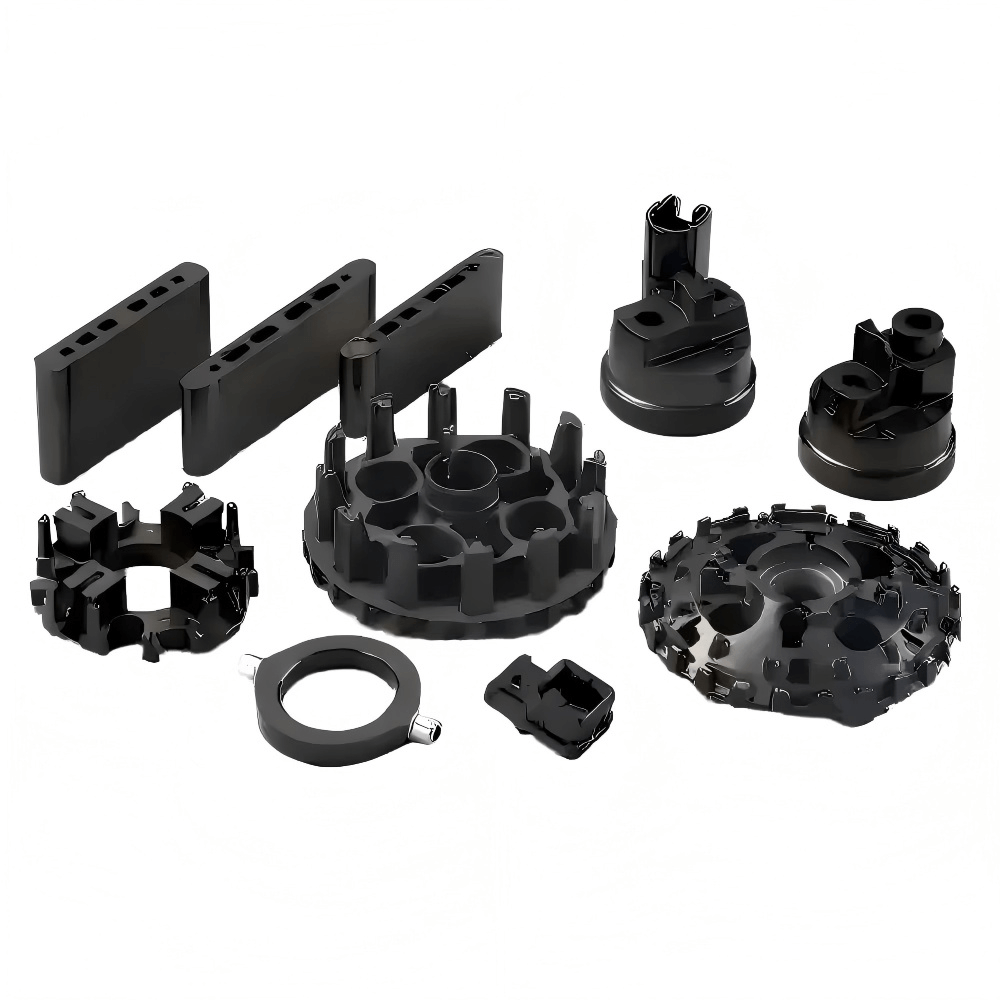

Plastic injection parts and machined plastic parts are plastic parts made by common processes. Today we will compare these two types of plastic parts from the perspective of materials, processes, costs, production efficiency, and applicable industries.

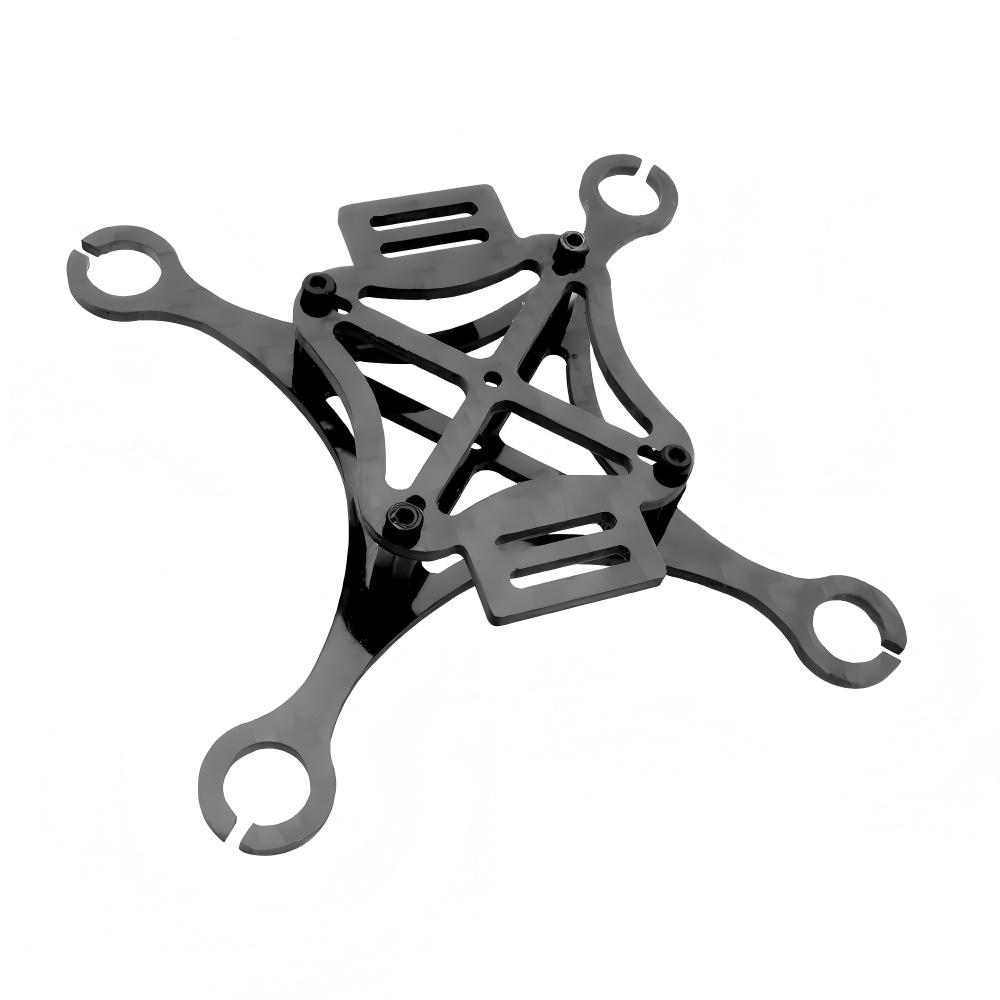

Injection molded parts mainly use thermoplastics such as PP, ABS, and PC, which are difficult to process for metals and composite materials. Machined plastic components can use high-strength engineering plastics, such as PEEK, POM, nylon, and some metal composite materials.

The process type of plastic injection parts is to inject molten plastic into the mold. Machined plastic parts are formed by removing materials such as cutting and drilling. The former is additive manufacturing with a tolerance of ±0.003 inches, and the latter is subtractive manufacturing with a tolerance of ±0.001 inches.

The mold surface of injection custom plastic parts directly affects the finish of the finished product, and usually does not require secondary processing. Machined plastic parts require additional polishing or sandblasting to eliminate cutting marks, which is suitable for products with high surface quality requirements.

The mold cost of injection plastic components is high, but the unit cost is low after mass production. Machined plastic components have no mold cost, but the unit cost is higher. Plastic injection molded parts have a short production cycle and are suitable for mass production, while machining plastic parts takes a long time.

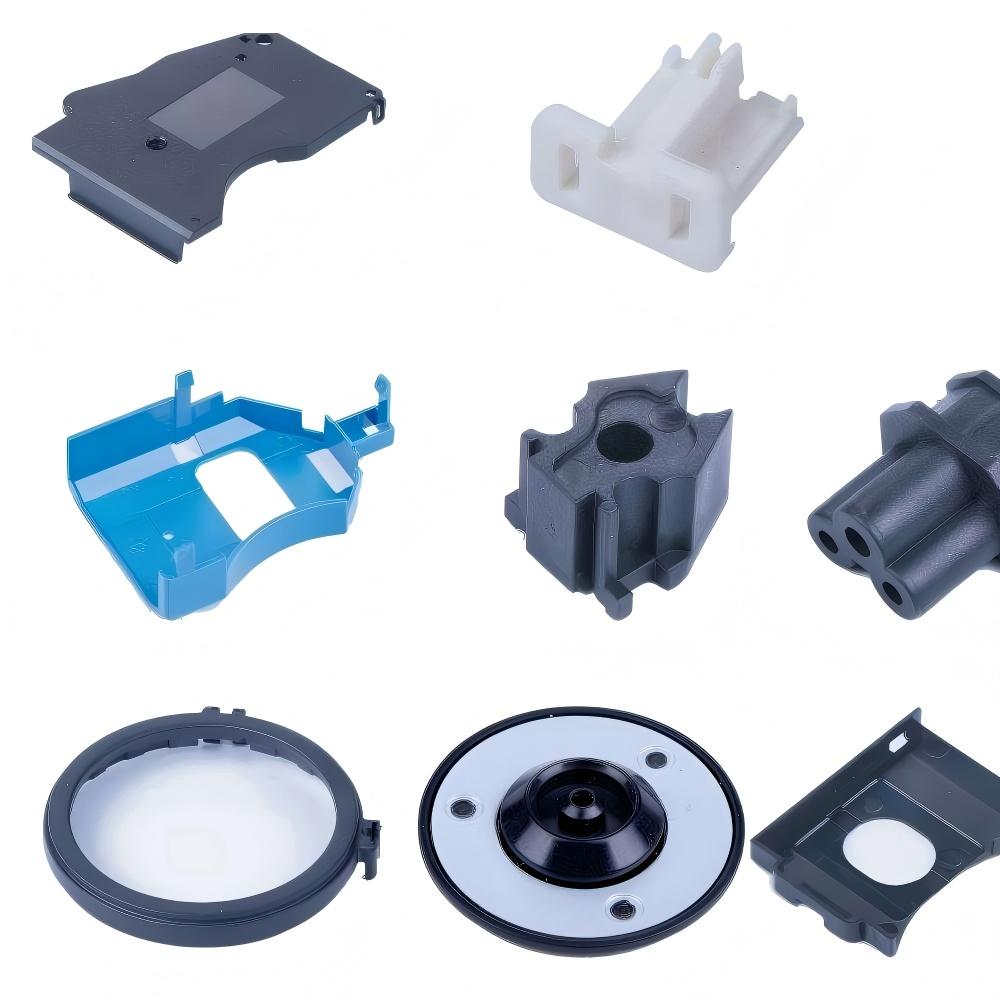

In the automotive manufacturing industry, plastic injection molded parts can be used for instrument panels and headlight housing parts, and machined plastic parts can be used as customized parts such as precision gears and sensor brackets. In the medical industry, plastic injection molded parts can be used as syringes and housing components. Machined custom plastic parts are used as surgical instruments and implants.

In electronic products, plastic injection molded parts can be used as mobile phone cases and electrical appliance housings, while machined plastic parts can be used as heat dissipation components and high-precision connectors. In the aerospace field, injection plastic parts can be used as interior trims and non-load-bearing structural parts, while machined plastic components can be used as high-temperature resistant brackets and lightweight load-bearing components.