What are the Manufacturing Difficulties and the Process of Sheet Metal Bending?

2025-08-04

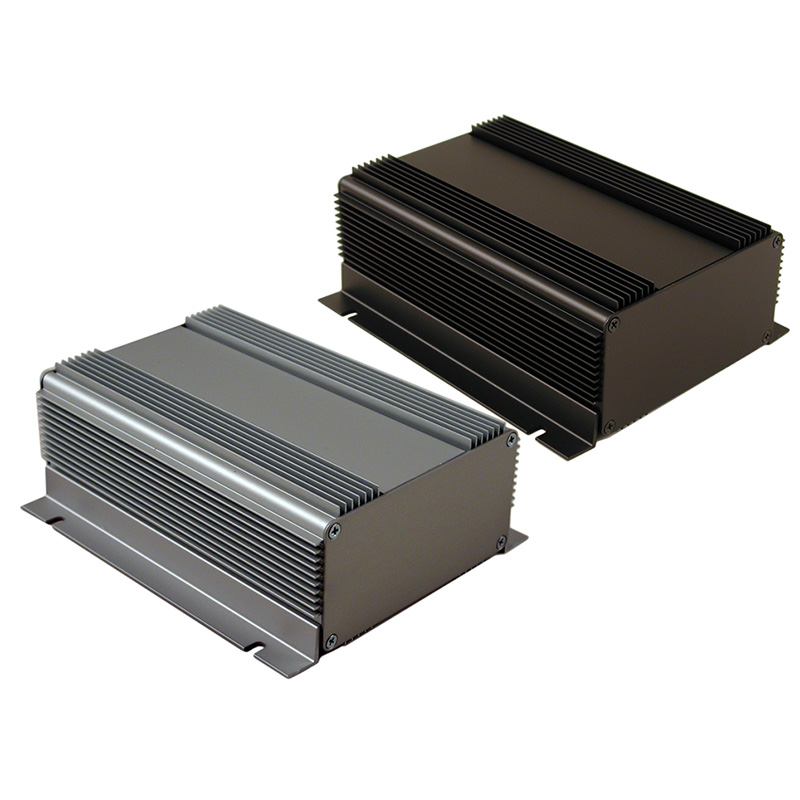

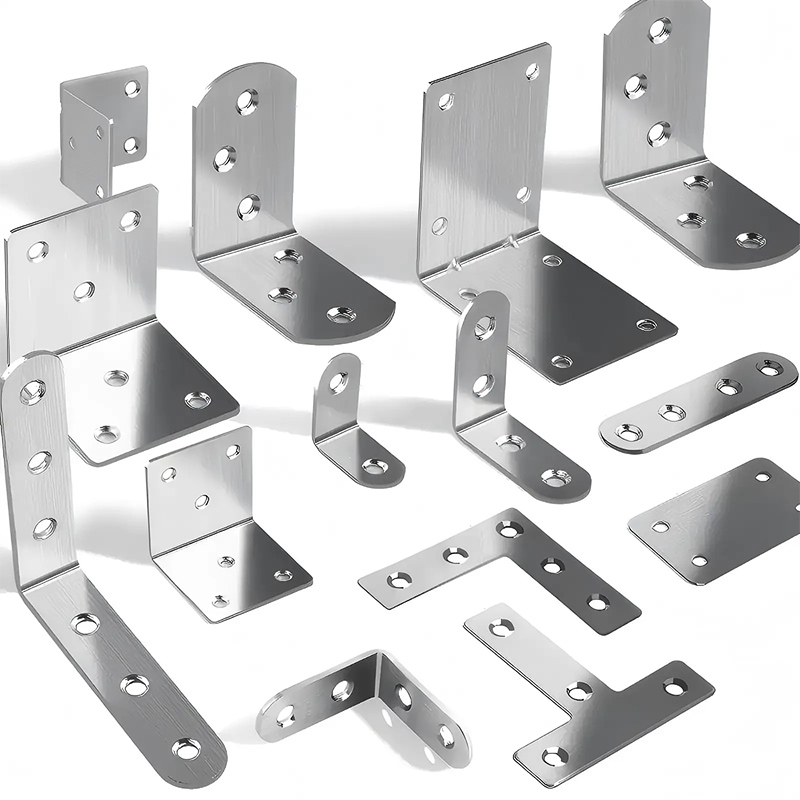

Custom sheet metal bending is bending sheet metal to special designs and angles, making sizes and shapes. In custom sheet metal fabrication, bending is a key step.

Design

Based on our customer requirements, Huaner manufacture custom sheet metal design drawings using CAD, including dimensions and bend angles.

We select the suitable material, such as stainless steel, aluminum, or copper sheet metal, and laser cut or stamp the sheet metal to the desired sizes.

Bending Tool

We choose bending die according to the thickness and bend radius of stainless steel sheet.

Then we adjust the CNC or manual press brake to ensure that the die and hold-down plate are correctly installed in the right place.

Bending

We place the aluminium sheet on the press brake, aligning it with the bend line.

We start the press brake and bend the sheet metal. And the complex shapes require multiple bends and rotations.

Post-Processing

After bending, we use a file or grinding wheel to remove burrs and sharp edges from the copper sheet metal edges.

Workers sand and polish the bent portion to ensure a smooth surface, free of scratches or bumps.

Quality Inspection

We use a projector to verify that the bent carbon steel plate dimensions meet design requirements.

We inspect the sheet metal surface for scratches, dents, or unevenness according to ISO 2768.

Sheet metal bending is a precise process, requiring specialized technology and equipment to ensure the final product meets customer’s specifications. We maintain strict precision control, achieving a precision hole tolerance of 0.02mm. Whether you're looking for a prototype or small-batch production, we can respond quickly and deliver the first sample within 7 days. Our advanced aluminum sheet metal processing equipment and technology, along with our experienced sheet metal workers, ensure you're ready to meet your sheet metal needs.