What are the Process, Application, and Advantages of Plastic Injection Molding?

Process Flow

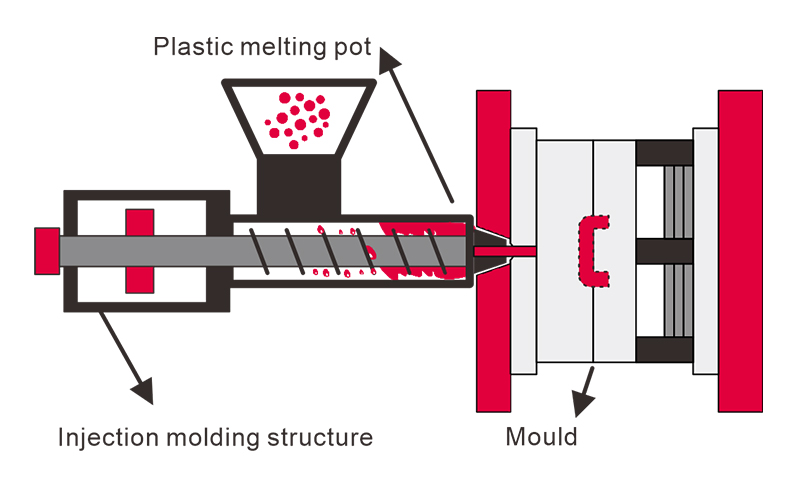

Plastic injection molding process consists of seven steps: drying, melting, high-pressure injection, pressure holding and shrinkage compensation, cooling and setting, mold opening and ejection, and post-processing quality inspection.

Plastic raw material pellets must be dehumidified. Materials like nylon must be dried at 80-130°C for 4-8 hours to prevent bubbles.

Plastic raw materials are heated and melted in the barrel. The temperature varies for different materials: PP: 160-175°C, PC: 270-300°C. The screw in the barrel rotates to ensure uniform flow.

The plastic melt is injected into the closed mold cavity at 70-150 MPa to fill the mold.

Maintaining machine pressure to compensate for cooling shrinkage requires precise control of the holding time to prevent sink marks.

Cooling and setting takes up 70-80% of the entire injection molding cycle. The mold temperature is controlled between 40 and 120°C to ensure that the plastic parts cool evenly and do not warp.

A mechanical ejector or robotic arm removes the product to avoid surface damage.

Workers remove extra plastic pieces and check how well plastic products work and fit together.

Applications

Plastic injection parts are used in various industries.

Daily Necessities: This injection molding process is rapid and cost-effective. Examples include tableware, storage boxes, and toys.

Automotive Parts: Complex-shaped products include instrument panels, headlight covers, and vent ducts.

Electronic and Electrical: Injection molding with an accuracy of ±0.1mm includes products such as mobile phone cases, keyboard keys, and connectors.

Medical Devices: Products requiring sterility include syringe casings and surgical instrument components.

Industrial: High-strength plastic products include gears, pipes, and valves.

Advantages

- The plastic molding process can be used with materials including PP, ABS, PC, PA, PE, and PLA.

- We offer PP disposable tableware, PLA phone cases, and TPR Spiky Balls.

- Huaner can make complex parts with threads and custom-shaped holes. It can meet all customer requirements.

- The plastic raw material utilization rate is over 95%, and the runner material is recyclable.

- The custom injection molding process can produce each piece in just a few seconds.

- Our dimensional tolerances meet the GB14486-2008 standard.