China rally bar mount Manufacturers, Suppliers, Factory

We believe in: Innovation is our soul and spirit. Quality is our life. Shopper need is our God for rally bar mount,rally bar wall mount,adjustable tv wall bracket,universal bracket for tv,tv bracket ceiling mount, our products have good reputation from the world as its most competive price and our most advantage of after-sale service to the clients。

rally bar mount, We've got been perfectly devoted to the design, R&D, manufacture, sale and service of hair products during 10 years of development. We now have introduced and are making full use of internationally advanced technology and equipment, with advantages of skilled workers. "Dedicated to providing reliable customer service" is our aim. We've been sincerely looking forward to establishing business relationships with friends from at home and abroad.

Hot Products

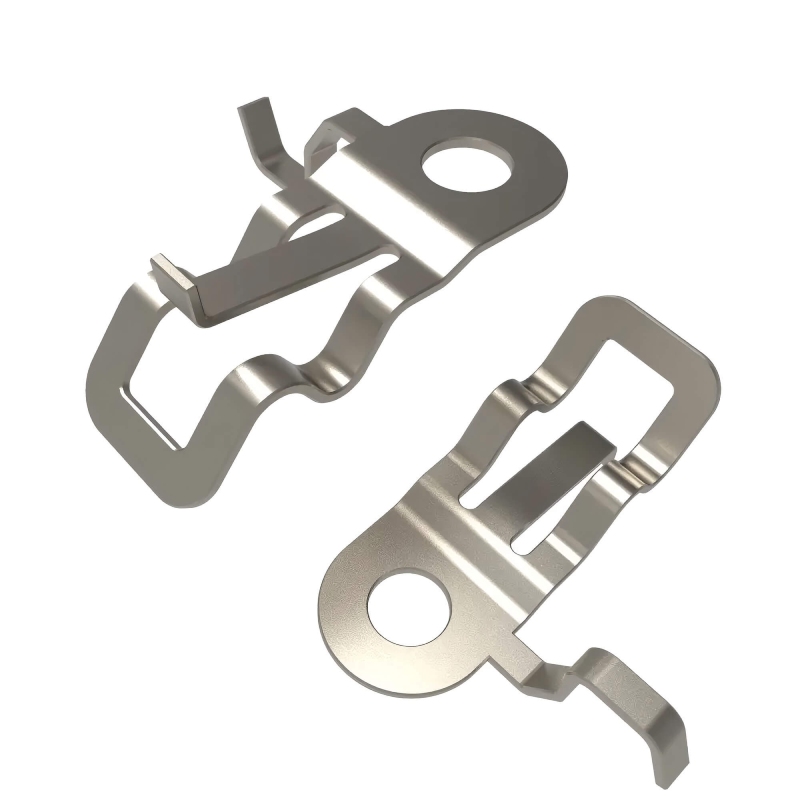

Sheet Metal Steel Spring Z Glazing Clips Hook

Huaner's sheet metal steel spring z glazing clips hook are rustproof and strong since they are made of premium 304 stainless steel, and they are available in a variety of sizes and forms.It may hold your distributor cap in place, link your penlight to your keychain, or keep your glove box securely closed. Whatever its purpose, using the four-slide technique is probably the best approach to do it. Nobody is more knowledgeable than fourslide spring and stamping on how to make your sheet metal steel spring z glazing clips hook.Furniture Hardware Hinges

The newest furniture hardware hinges are made of movable components or foldable materials. Xiamen Huaner Technology Co., Ltd., an advanced hinge manufacturer from China, produces mature, high-precision, high-quality hinges with a simple and charming appearance. The easy-maintainable furniture hardware hinges are primarily installed on doors and windows, while the classy damping hinge is mainly used for cabinets.Angle Brackets For Wood House Constructions

Standard Thick Galvanized DecorativeWood Angle Stainless Steel Corner Bracketfor securing wooden frames tables chairs bed furniture and other DIY structural.TheAngle brackets for wood house constructionsis made of high-quality stainless steel, which is rust-proof, sturdy and durable, and has smooth edges without burrs, so you don't have to worry about scratching your hands during use of the furniture.3 Way Ball Valve

Xiamen Huaner Technology Co., Ltd. is a professional manufacturer of 3 Way Ball Valve, which is dedicated to providing high-quality and high-performance fluid control solutions. Our 3 Way Ball Valves are widely used in petroleum, chemical, water treatment and other fields because of their durability, easy operation and excellent sealing performance. With advanced production equipment and strict quality control, we not only provide cost-effective products, but also customized solutions to meet diversified application needs.Stainless Steel Kitchen Cabinet Wardrobe and sofa Hinge

Stainless Steel Kitchen Cabinet Wardrobe and sofa Hinge is a mechanical device used for doors or windows. Double spring hinge manufactured by Xiamen Huaner Technology Co., Ltd. is widely used in commercial buildings, public facilities and family houses as it is made of high-strength materials to ensure a long service life under frequent use. Meanwhile, we focus on customer needs and provide flexible customization services to meet the demands of different markets.Metal Stamping Parts

Huaner is a metal stamping parts manufacturer in China. The stamping parts we produce can be made of stainless steel, aluminum alloy, carbon steel and other materials with an error of 0.01-0.1mm. Sheet metal stamping parts can be used for automotive parts, railroad parts, medical parts, marine parts, lighting parts.