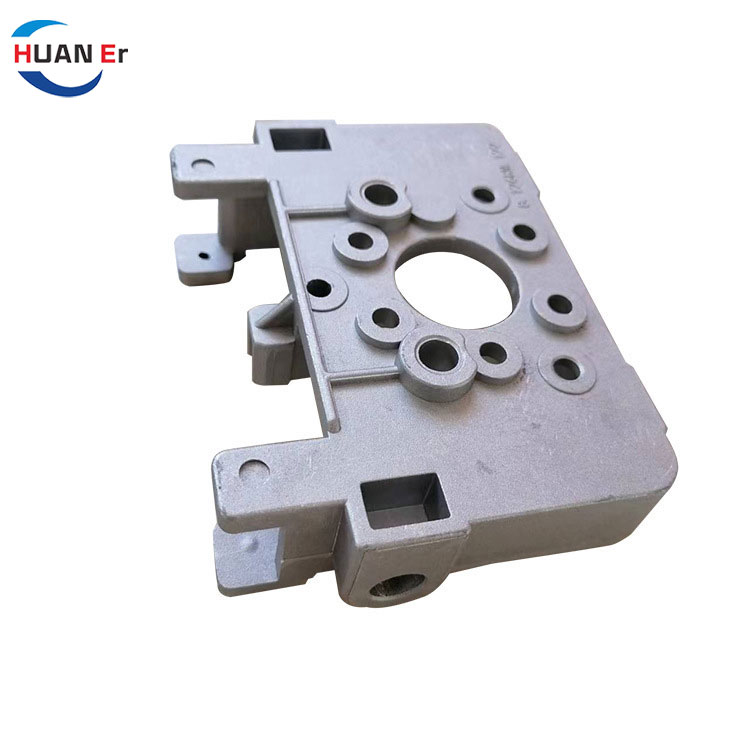

Zinc Die Casting Components

Zinc die casting is a process that involves melting zinc alloys and inject zinc alloy into a ready die casting mold. Zinc alloys are widely used in manufacturing spare parts because of their ductility, impact strength, and low melting point.The produced zinc die casting components have many advantages.

Send Inquiry

Zinc Die casting components

Zinc is one of the most multifunctional die cast metals. Zinc die casting components can provide high precision with low tooling costs when compared to aluminum alloy die cast . Zinc die casting also offers a wide range of excellent physical and mechanical properties, finishing features, it is the easiest to cast.

Advantages of zinc die casting components

The most featured advantages of zinc die casting components is that it can reduce tooling costs. Die cast tooling is typically an important cost factor. Small zinc parts can utilize the high-speed 4-slide miniature zinc die casting process, which allows for significantly lower upfront tooling components when compared to aluminum or magnesium. Zinc die casting components feature longer tool life, lower tooling cost,it can die cast net shaped complex geometries with thinner walls and less draft angle,excellent balance of mechanical and physical properties, higher yield strength and elongation,good vibration dampening capacity ,wide range of surface treatments, faster production time.

The advantages above of zinc allow it to be used in a wide range of industries and applications.

The Zinc Die Casting Process

Zinc is casted with the fast-cycling hot chamber die casting process, which utilizes a component called a gooseneck that is submerged in a furnace filled with molten metal. Metal automatically enters the shot chamber through a hole in the gooseneck. A vertical plunger then seals the hole and drives the metal into the back of the die with high pressure. The part rapidly solidifies (within seconds), and the part is ejected from the tool.

Zinc Alloys Available at Huaner

Huaner casts two different zinc alloys: Zamak No. 3 and ZA-8. Both offer the ability to cast with intricate detail and close dimensional tolerances at high production

Is zinc good for die casting?

The strength, ductility and stability of zinc allows us to obtain a better and more resistant product. It is this high ductility that makes zinc ideal for die casting process, in which it is necessary to sustain pressure and expansion without fracturing.

What material is used in zinc casting molds?

Zinc die casting is a metal casting process where molten zinc (often a ZAMAK Alloy) is forced into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process.

What are the advantages of zinc alloy?

Benefits of Zinc Alloy

● Lower cost compared to steel.

● Dimensional consistency for high product quality.

● Inherent corrosion protection.

● Functional advantages that ensure trouble-free installation.