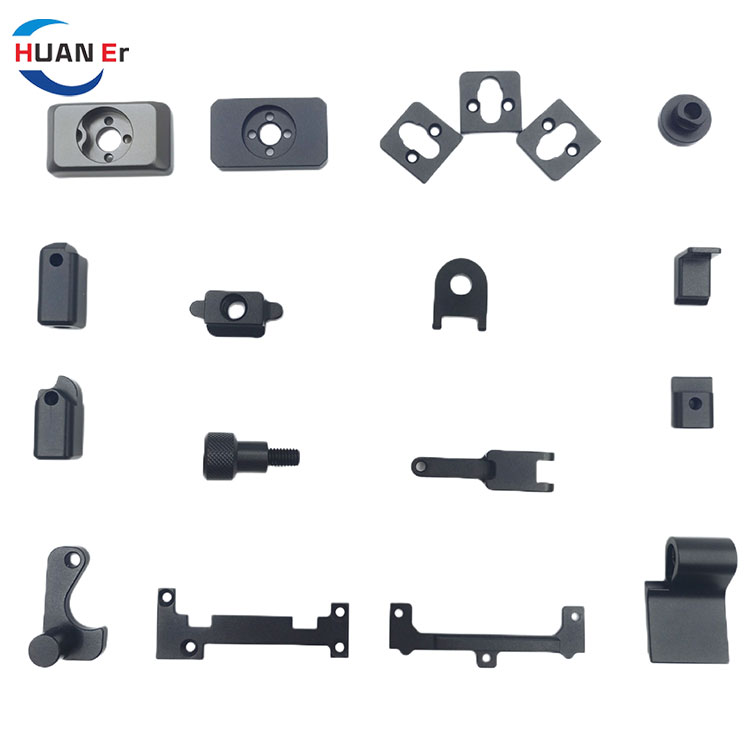

CNC Aluminum Machinery Parts

Huaner Company, as a seasoned manufacturer in the field of CNC aluminum machinery parts, drawing on years of industry experience and technical expertise, is capable of providing a diverse range of solutions for CNC aluminum machinery parts across various industries. With the custom services offered by Huaner Company, you can tailor-make CNC aluminum machinery parts that meet your specific functional and performance requirements, thereby enhancing the market competitiveness of your products.

Send Inquiry

Through Huaner Company’s custom services, customers can not only obtain CNC aluminum machinery parts that meet their specific needs but also enjoy a one-stop service from design to production and delivery. This customized solution not only enhances the performance and quality of the products but also helps customers shorten the time to market and reduce costs, ultimately standing out in the fierce market competition.

CNC aluminum machinery parts are renowned for their lightweight and high-strength properties, with a density of only one-third that of steel, making them lightweight and easy to handle and install, while also possessing sufficient strength to bear mechanical loads. Their good machinability allows for the precise production of complex-shaped parts, and the dense oxide film on their surface endows them with excellent corrosion resistance, suitable for a variety of environments. Aluminum alloy also has good thermal and electrical conductivity, although not as high as copper, it is still applicable in the electrical industry. Moreover, its recyclability and the smooth, aesthetically pleasing appearance it can achieve after treatment make it highly favored in environmentally friendly and high-appearance requirement products. Common aluminum alloys such as 6061, 7075, 5052, and 2024 each have their own characteristics and are suitable for different fields; the correct selection of these materials is crucial for ensuring the performance and extending the service life of CNC aluminum mechanical parts.

The exquisite craftsmanship of CNC aluminum machinery parts is reflected in the meticulous operation and strict quality control at every stage of production, from the precise design drawings to the final product, with every step embodying the spirit of craftsmanship and technological innovation. This craftsmanship starts with high-precision design, selects high-quality aluminum materials, goes through precise programming and CNC machining, and then to detailed surface treatment, as well as rigorous quality inspection and assembly debugging, ensuring the high performance, reliability, and aesthetics of the parts, thus meeting the stringent requirements of various industries for high-quality machinery components.

CNC aluminum machinery parts play a significant role in various industries due to their unique material properties, not only improving the performance of products but also reducing costs and enhancing the market competitiveness of products:

Automotive Manufacturing: Applied to automotive parts such as engine components, transmission parts, suspension system accessories, and body structures, it helps to enhance the performance and fuel efficiency of cars.

Electronic Communication: Used in the heat dissipation parts, shells, and brackets of electronic devices, its good thermal conductivity and lightweight characteristics contribute to the device’s heat dissipation and portability.

Automation Equipment: Serving as components of various robotic arms, transmission systems, fixtures, and molds in automated production lines, it improves production efficiency and precision.

Precision Instruments: Used in the manufacture of precision equipment parts such as measuring instruments and analytical devices, ensuring the accuracy and stability of the equipment.

Construction Industry: Used in building structural components, decorative items, and window and door frames, its corrosion resistance and aesthetic appeal make it suitable for both outdoor and indoor environments.

Medical Devices: Used in the manufacture of surgical tools, rehabilitation equipment, and structural components for medical devices.

Energy Sector: Used in renewable energy equipment such as wind and solar power, for making supports and connectors, adapting to harsh environmental conditions.

Military Equipment: Used in military equipment parts such as drones, armored vehicles, and communication devices, meeting the special needs of the military field.

By choosing Huaner’s CNC aluminum machinery parts, your company can not only obtain high-quality products but also leverage Huaner’s resources and expertise to more effectively expand into international markets and enhance global competitiveness.