PLA Phone Case

Huaner is a leading supplier in producing PLA phone cases. Our biodegradable cases offer laser engraving logos and can be embossed using PLA thermoplastics. The compostable phone cases are impact-resistant, heat-resistant, lightweight, and fully degrade in 1-3 years. We provide OEM/OEM services with biodegradable packaging solutions.

Send Inquiry

The PLA phone case is made of three raw materials: PLA, PBAT and bamboo fiber by low-temperature injection molding. The biodegradable phone case is environmentally friendly, healthy, comfortable, drop-resistant and anti-deformation. The carbon emissions of PLA raw materials are only 10%-15% of traditional plastics. PBAT absorbs energy, and the eco case can resist drops and buffer; the surface hardness of bamboo fiber is high, so it is scratch-resistant and wear-resistant. The compostable phone cover is suitable for common models, and special models can also be customized. The density of bamboo fiber particles can be adjusted to form striped/spotted textures; PLA+water-based environmentally friendly dyes support Pantone color customization.

Material Technology

The compostable phone case uses the innovative environmentally friendly composite material technology of PLA+PBAT+bamboo fiber, achieving a balance between performance and environmental protection:

PLA bio-based main body - derived from corn starch, provides hardness and rigidity, 100% compostable and degradable;

PBAT flexible modification - petroleum-based degradable polyester (accounting for 20-30%), significantly improving the anti-fall performance (1.5 meters drop without damage);

Bamboo fiber reinforcement - 30% content of short-cut fiber, through patented interface processing technology, the tensile strength is increased by 50% to 65MPa.

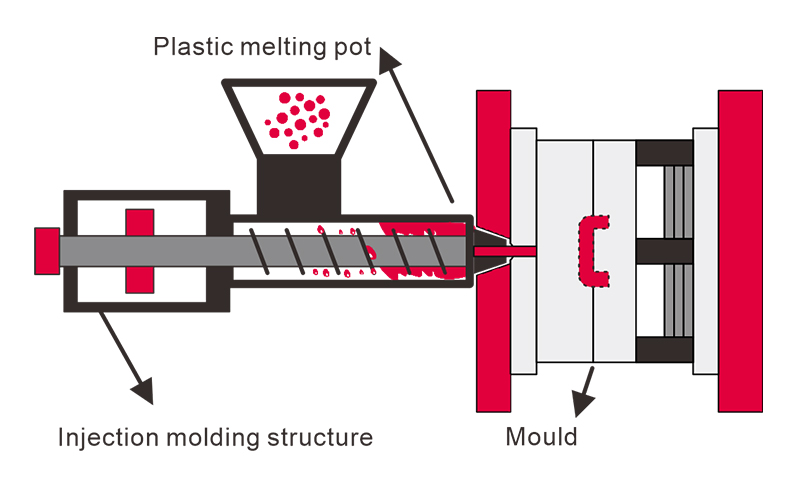

Low Temperature Injection Molding & Quality Control

The production of sustainable iphone cases involves four stages: plasticization, injection, packing, cooling and demolding. The plastic particles are heated to a molten state (170-185℃) in the barrel; the screw injects the melt under 60-80MPa injection pressure; packing pressure of 30MPa compensates for shrinkage until gate solidification; the PLA phone case is ejected after water cooling (15-20 seconds). Huaner has strict quality control: online infrared monitoring of melt uniformity, random inspection of dimensional tolerance (±0.15mm) for each mold, and 48-hour environmental chamber test (50℃/95%RH) to verify that the deformation rate is less than 0.3%.

Customization and Packaging

Laser engraving LOGO: Eco friendly phone cases support fine engraving of corporate logo depth ≤ 0.3mm (compatible with bamboo fiber structure).

Natural texture design: Retain the natural texture of bamboo fiber, provide environmentally friendly color options such as original wood color/carbonized color.

Environmentally friendly ink printing: Huaner use water-based pigments to print patterns (VOC emissions reduced by 80%)

Compostable packaging bags (PLA+starch-based materials)

Customized environmentally friendly instructions (printed with soy ink)