China auto parts Manufacturers, Suppliers, Factory

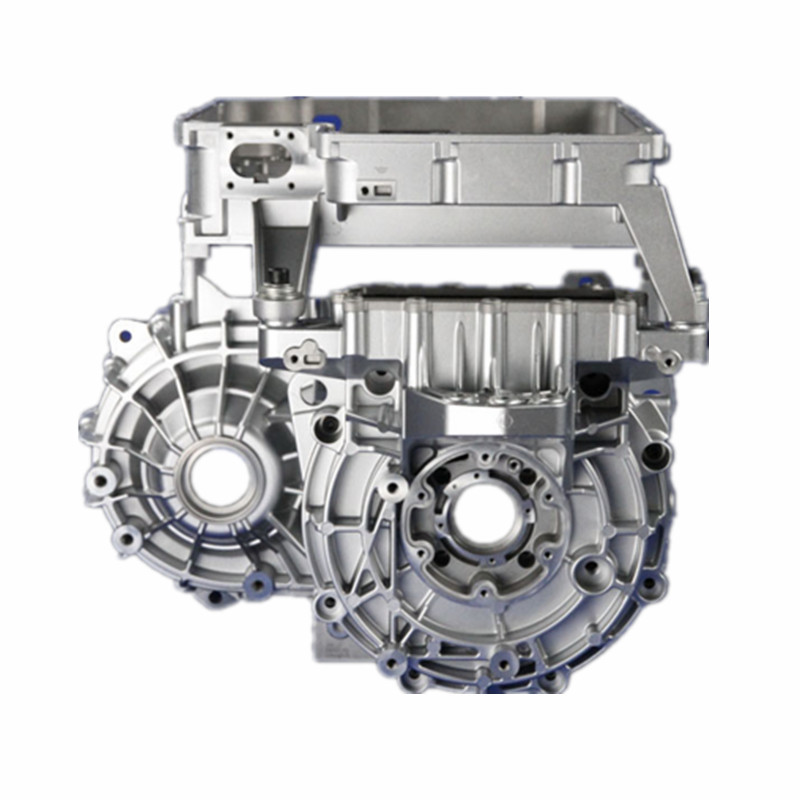

We also offer product sourcing and flight consolidation services. We have our own factory and sourcing office. We can provide you with almost every type of product related to our product range for auto parts,Sheet metal auto parts,Car die casting parts,Stainless steel auto parts,precision sheet metal components, Welcome all customers of property and abroad to go to our organization, to forge a fantastic long run by our cooperation.

auto parts, Now we have constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and professional after-sale service supplied by our consultant group has happy our buyers. In depth Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Hot Products

Metal High Speed Production Printer Case

Metal high speed production printer case is a kind of printer case made of metal materials, which is designed for high-speed printing and meeting various industrial printing needs. Metal high speed production printer case Manufactured by Xiamen Huaner Technology Co., LTD is generally made of high-quality aluminum alloy materials, which has the advantages of high precision, light weight, good temperature resistance and good corrosion resistance. In addition, the printer case has a more stable performance and a longer service life.Stainless steel bathroom shower Angle valve

Stainless steel bathroom shower Angle valve is a high-quality stainless steel bathroom accessory, it has excellent corrosion resistance and wear resistance, can withstand a long time of use. Xiamen Huaner Technology Co., Ltd. Wholesale for the design of the Angle valve is more sensitive and high-quality, the design of the Stainless steel bathroom shower Angle valve is very humanized, can easily adjust the shower water way and temperature, to meet the needs of different people.Hardware Nuts And Bolts

Hardware nuts and bolts are indispensable parts in the field of machinery, Xiamen Huaner Technology Co., Ltd. is a manufacturer and seller of nuts and bolts. They play an important role in various engineering, construction, automotive, aviation and other industries. With the advancement of science and technology and the development of industry, the types and performance of hardware nuts and bolts are also constantly improving to meet the increasingly stringent requirements of use. This paper will briefly introduce the basic concept, classification and application of hardware nuts and bolts, and discuss its development trend.Double Spring Hinge

Double spring hinge is a mechanical device used for doors or windows. Double spring hinge manufactured by Xiamen Huaner Technology Co., Ltd. is widely used in commercial buildings, public facilities and family houses as it is made of high-strength materials to ensure a long service life under frequent use. Meanwhile, we focus on customer needs and provide flexible customization services to meet the demands of different markets.Disposable Cutlery

Huaner is a disposable cutlery manufacturer in China. We provide high quality plastic cutlery set, using plastic injection molding process. Disposable plastic knives, forks and spoons are durable and safe, and we can produce thousands of sets every day.Slow Feeder Bowl

Huaner is a supplier of slow feeder bowls with a factory. Its dog food slow feeder is made of PP material and formed in one step through the injection molding process. This process complies with FDA/GB standards. The bowl is frosted or sandblasted and has an antibacterial coating.