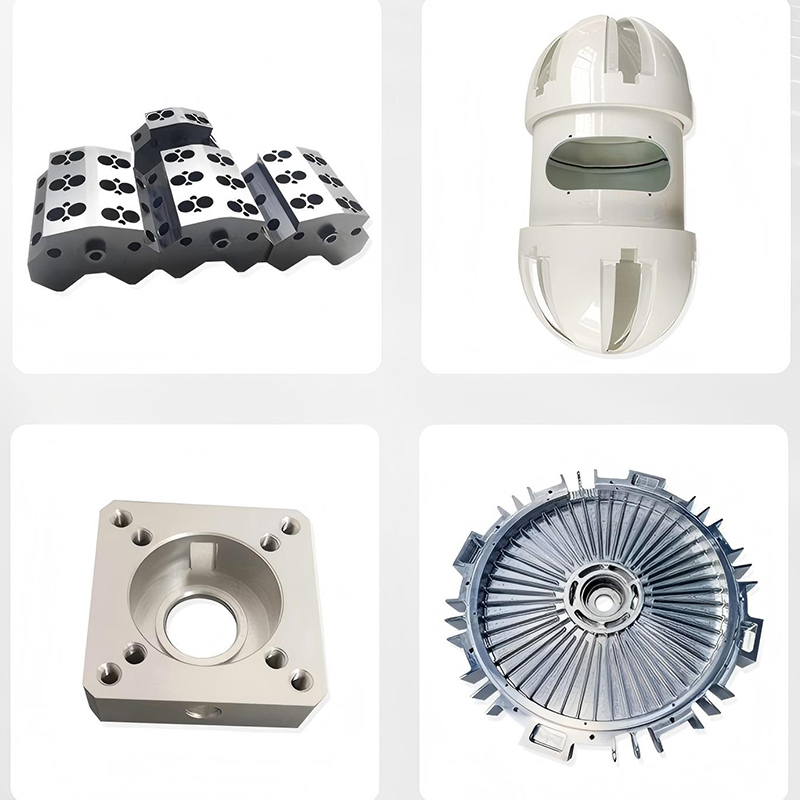

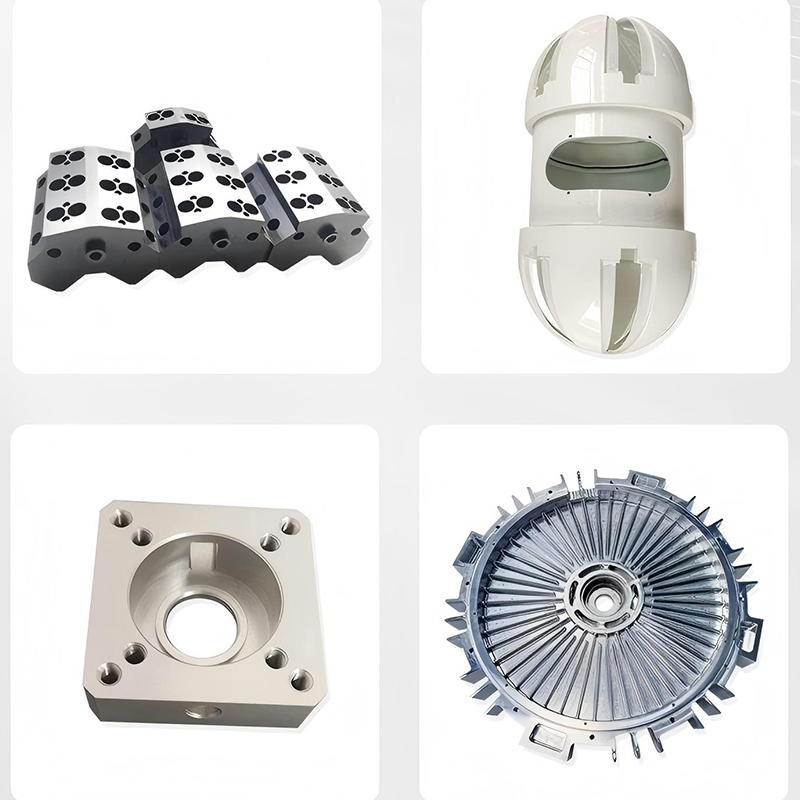

CNC Metal Parts

Huaner is a CNC metal parts manufacturer that owns a factory. We offer custom CNC machining services, including professional production techniques and surface treatment. We are ISO and RoHS certified. We deliver CNC precision parts in 7-14 days.

Send Inquiry

CNC metal parts are digitally controlled and can achieve a tolerance of ±0.01mm. Parts with extreme precision requirements like engine parts can also be produced.

CNC can process complex products. Five-axis technology can manufacture special-shaped structural parts and non-standard parts, such as special products such as medical device implants.

CNC is an efficient and automated process that can produce 24 hours a day with a yield rate of more than 90%. Customers don't have to worry about the quality of Huaner's CNC parts.

CNC is compatible with and uses many materials, such as stainless steel, titanium alloy, engineering plastics and other materials.

CNC programming can be adjusted quickly, suitable for small batch customized production, and customers can flexibly customize products.

Production Process

Milling: Rotating multi-blade tools can cut out custom CNC parts with complex shapes such as gear grooves and mobile phone shells, with an accuracy of 1/10 of a hair.

Turning: When the workpiece rotates, the tool turns out a cylinder or thread, which is suitable for cnc milling parts such as screws and bearing sleeves.

Five-axis machining: The tool can be tilted and rotated to create curved surfaces such as aircraft turbine blades like a 3D printer.

Quality inspection: finished CNC metal parts are inspected for quality using a three-coordinate measuring machine, and a laser probe scans every corner of the part to ensure that the dimensional error does not exceed 0.01mm.

Surface Treatment

Anodizing: Machined aluminum parts are soaked in electrolyte and energized to form a honeycomb oxide film on their surface, which is both rust-proof and can be dyed into colors (such as the frame of an iPhone).

Electroplating: Similar to "gold plating" metals, such as the common chrome-plated car exhaust pipes or nickel-plated faucets, which are corrosion-resistant and shiny.

Sandblasting: Use high-speed sand to bombard the surface, so that the CNC turned parts have a frosted texture, which is similar to a frosted mobile phone case.

Mirror polishing: The cloth wheel plus abrasive paste repeatedly polishes the parts to achieve a mirror-like smoothness, such as stainless steel tableware.

Laser marking: Use laser to engrave the logo on parts, commonly used in medical devices.

Teflon coating: The same technology as non-stick pans, used on CNC precision parts to prevent sticking and reduce friction.