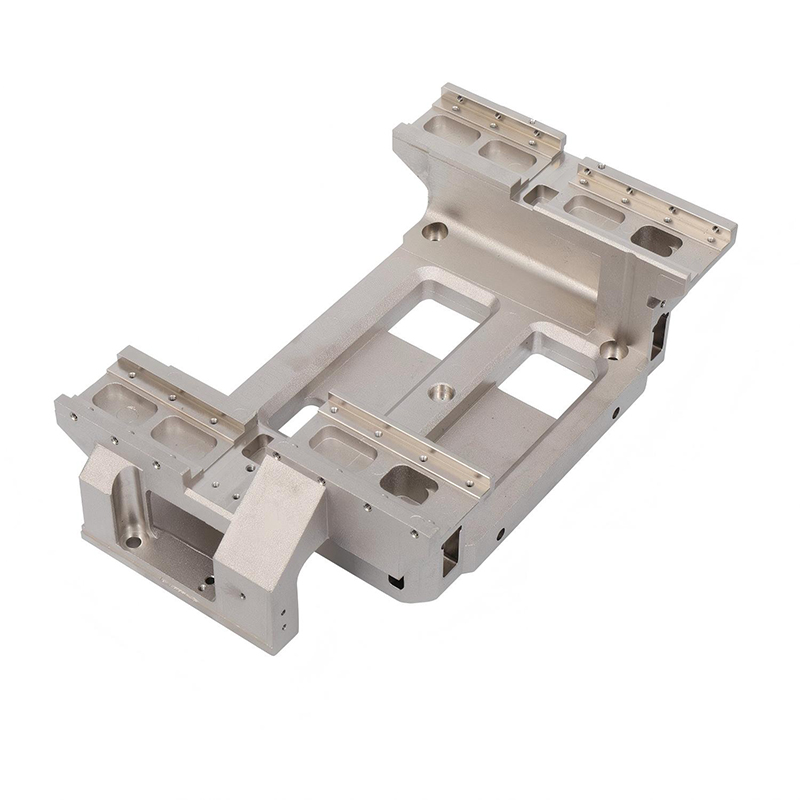

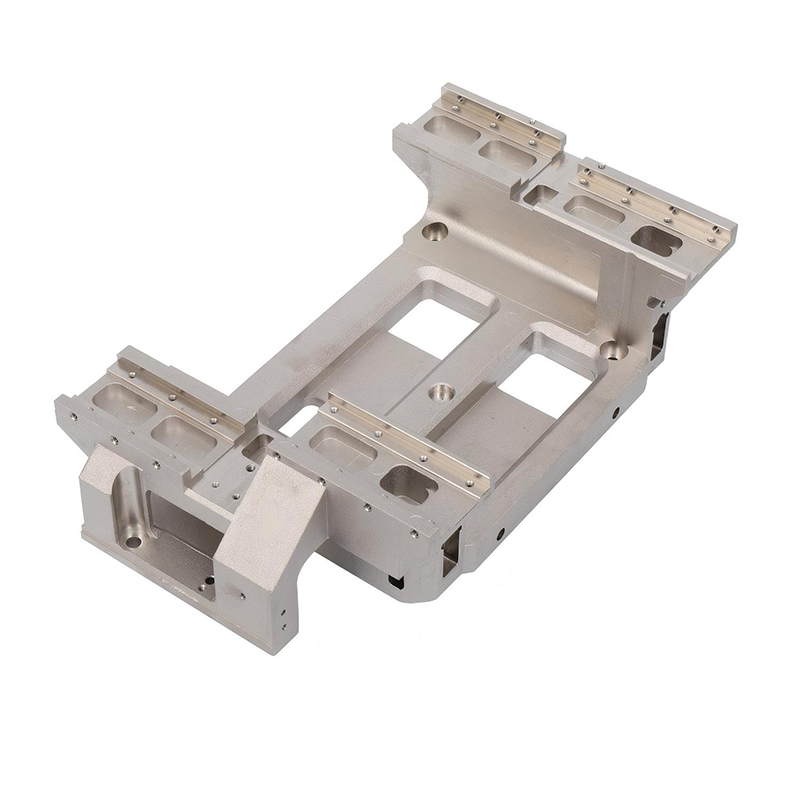

Die Casting Parts

Huaner is a precision die casting parts manufacturer with a factory in China. We offer OEM production and full R&D solutions for cast aluminium parts, and our products are ISO/TS16949 certified. We also offer cost-effective mass production and lead times of 7–15 days.

Send Inquiry

Various die casting parts have the following ways to improve their appearance and surface properties.

Powder Coating: automotive castings are sprayed with paint or powder to enhance their corrosion resistance, and colors can also be customized.

Electroplating: The housing of electronic equipment is plated with zinc, nickel or chromium to make it more wear-resistant.

Anodizing: Aluminum die castings, such as 3C products, are commonly used to form an oxide film on their surface to enhance hardness.

Polishing/sandblasting: Lighting decorative parts are deburred or matte and glossy.

Production Process

High-pressure die casting process produces parts, which go through mold design, melting and injection, post-processing and other steps.

To ensure smooth demolding, the steel mold parting surface of the mold needs to be precisely processed.

After the metals such as aluminum alloy and zinc alloy are melted, they are injected into the mold with 1000-2500 psi high pressure and then cooled to form.

Finally, the parts are deburred and heat treated, or machined by drilling and milling.

Application

Our die casting components are suitable for different industries.

Automobile: lightweight engine bracket, gearbox housing.

Electronics: radiator and mobile phone middle frame made of high thermal conductivity aluminum die casting process.

Home appliances: low cost, mass-produced washing machine motor housing and air conditioning components.

Industry: high-strength die cast zinc pump body and gearbox.

Services

Customers provide die casting products design, and our factory mass produces according to the drawings. Or Huaner provides a full set of solutions from R&D to mass production.

Our large-scale production can reduce the cost of each unit, and the mold sharing cost is clear, so as to achieve the best cost control.

We have IATF 16949:2016 certification system, provide full inspection reports of size, leak testing and hardness, and ensure quality.

Our delivery time is flexible, 7-15 days for standard parts, and expedited delivery for complex parts can be negotiated.

Specification

| Material | Zinc/Aluminum Alloy, Brass, etc. |

| Forming Process | Die Casting, Sand Casting |

| Mechanical Processing | Lathe, Drilling, Grinding, Cutting, Milling |

| Surface Treatment | Sandblasting, Electroplating, Powder Coating, Anodizing, Mirror Polishing, Chrome Plating, Nickel Plating |

| Tolerance | ±0.02mm |

| Application | Die casting parts, applicable to home appliances, car parts, furniture components |

| Certifications | ASTM, ISO, BS, API, EN, GB, etc. international/domestic standards |

| Packaging | Packed in cartons and placed in wooden crates, or as per customer requirements |